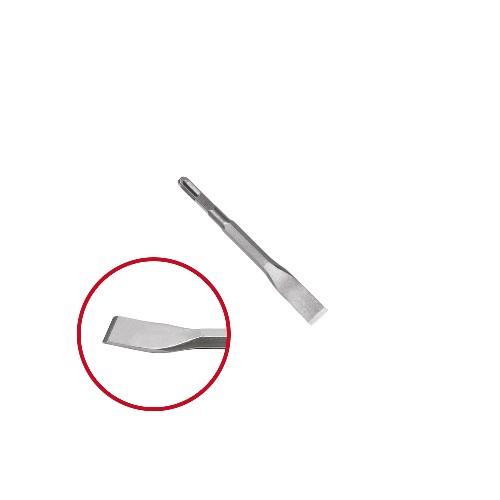

The use of an electric pick chisel

Hammer chisel is a kind of power tool, also known as the electric hammer, it is mainly used to help workers hammer, chisel, digging and a series of work on the site. It has a wide range of use, and can be used in construction, geological exploration, road laying, digging, dredging, cleaning up masonry and other occasions.The following is the specific use of the hammer chisel:1. Construction field: pickaxe chisels can be used to punch holes or open shallow walls, floors or ceilings in order to repair wires and cables, water pipes, gas pipelines, etc. In the case of demolition to protect the surrounding buildings or structures, it is necessary to use the pick chisel, which can more accurately control the force, so as to avoid damage to the external environment. At the same time, it is also needed in building renovation and decoration, such as making holes, planing boards and digging holes on walls, floors and ceilings.2. Geological exploration: pickaxe chisels are often used for geological exploration, which can be used to drill samples, drill, blast and other work in order to collect geological data, explore mineral veins, mining minerals, and build buildings.3. Road laying: When laying the road, it is necessary to cut the opening with an electric pick chisel on the ground to facilitate the pipeline.

2023-09-04MORE